Production

Production

Testing the upper use temperature of perfluoroelastomers

The market for industrial-use elastomers is defined by extremes. Whether chemical compatibility, plasma resistance, high and low temperatures, or other characteristics, engineers demand the highest possible performance. By Dr Thomas Reger, Senior Scientist at Greene, Tweed

High quality and innovative materials for optimum performance

When choosing the appropriate material, users should always consider the area of application. Here Marcus Schneck, CEO of norelem has explained why it is crucial to use operating parts made of high-quality materials as this can ensure the reliability and stability of the components used and products produced.

An valid alternative to conventional machine tooling

Gerard Young, Applications Engineering Team Leader, Parker Hannifin – Chomerics Division Europe, explains that 3D printing for prototyping EMI housings and gaskets is breaking new ground.

3D printing accelerates tissue engineering research

Formlabs, the designer and manufacturer of accessible 3D printing systems, is working with Dr Sam Pashneh-Tala, Research Fellow at the University of Sheffield, who is leading pioneering tissue engineering techniques for creating complex, lab-grown, blood vessels with patient-specific shapes, powered by Formlabs SLA 3D printers.

Form and Function with 3D Electronics

Since the inception of electronic devices there have been radical improvements in performance and miniaturisation. However, the form of electronics has barely changed – typically discrete components are mounted on circuit boards which are put in a box. By Raghu Das, CEO, IDTechEx

What are the challenges of stretchable electronics?

Stretchable Electronics (SC) is already commercial and comes in many shapes and forms. The panel of images below showcases a number of prototypes and products which utilise a stretchable component and/or material. These pictures have been mainly (not entirely) taken by IDTechEx analysts at events around the world during the past five years.

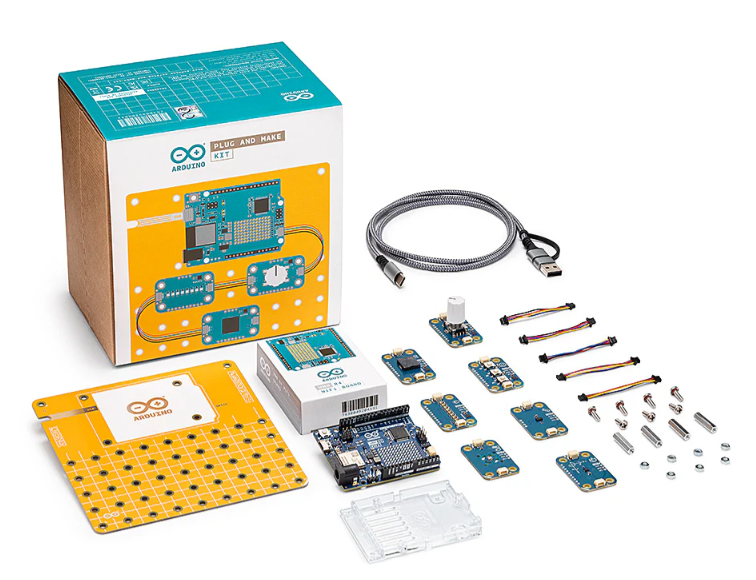

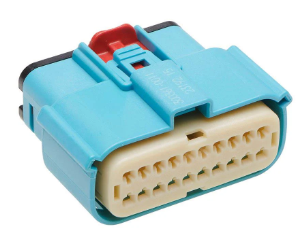

How to address the challenge of long lead times

For original equipment manufacturers (OEMs), securing appropriate levels of inventory for long lead time components and sub-assemblies is a costly, time-consuming and perennial challenge. Increasingly OEMs are outsourcing, but choosing the right supply partner can make all the difference to companies looking to boost their competitiveness in a rapidly changing market. Paul van der Tang, Purchasing Director of Offshore Electronics explains.